Why Transparency and Partnership Are the Future of Supplement Manufacturing

In today’s competitive and fast-evolving nutraceutical landscape, the expectations for quality, ethics, and accountability have never been higher. Brand owners are under pressure not just to deliver effective products but to do so with complete clarity about what’s inside them, how they’re made, and who they’re made by.

As a result, two pillars have emerged as the defining traits of top-tier supplement manufacturing: transparency and partnership. Together, these values not only build trust with consumers but form the foundation of long-term success for brands and their manufacturing partners alike.

This article explores why transparency and partnership are now essential in nutraceutical manufacturing—and how manufacturers can elevate both to help brands grow stronger and more sustainable in 2025 and beyond.

The Shifting Expectations of the Modern Supplement Consumer

The modern consumer is savvy, health-conscious, and informed. The rise of digital information and social media has made it easy for consumers to research ingredients, demand clean labels, and expect ethical sourcing. But their scrutiny doesn’t end at the bottle—it extends through the entire supply chain.

A few key shifts in consumer behavior are driving this change:

- Demand for Clean Labels: Consumers want to understand exactly what they’re ingesting. Terms like “non-GMO,” “vegan,” “organic,” and “gluten-free” are no longer value-adds—they’re often deal-breakers.

- Ingredient Traceability: Buyers want proof that ingredients are responsibly sourced and validated for quality and safety.

- Social Responsibility: From environmental sustainability to fair labor practices, people want to know their favorite brands are doing the right thing.

As a result, nutraceutical brands must choose manufacturing partners who are fully transparent about their practices—because their reputation depends on it.

What True Transparency Looks Like in Supplement Manufacturing

Transparency is more than a buzzword—it’s a system. It’s about clear communication, open data, and full visibility into what goes into your products and how they’re made.

Here’s what transparency looks like when it’s done right:

1. Detailed Documentation at Every Step

From raw material sourcing to finished product testing, transparency means thorough documentation of every phase of production. This includes:

- Ingredient COAs (Certificates of Analysis)

- Batch records

- Allergen statements

- Lab testing results

- Stability studies (where applicable)

The wrong manufacturing partner can slow you down, burn your budget, and introduce compliance risks. The right partner can help you build a strong foundation for future scale.

2. Open Communication & Real-Time Updates

The best manufacturers provide frequent, clear updates on:

- Production timelines

- Ingredient sourcing issues

- Formula challenges or optimization opportunities

- Regulatory changes that may affect your label or formulation

This helps brand owners stay agile and proactive rather than reactive.

3. Third-Party Testing & Verification

Independent verification builds confidence with retailers and consumers. A transparent manufacturer doesn’t just rely on internal QA—they embrace third-party testing as a critical part of their quality assurance.

4. Facility Access (Physical or Virtual)

When possible, allowing brand partners to visit or virtually tour facilities promotes trust and reinforces a shared commitment to high standards.

Why True Partnership Goes Beyond the Contract

While transparency is essential, it means little without a strong relationship behind it. That’s where partnership comes in.

A manufacturer that acts as a true partner will:

1. Invest in Your Long-Term Success

Rather than focusing on quick transactions, the best manufacturers think long-term. They help you navigate challenges, innovate new products, and adapt to changing market demands.

2. Offer R&D Collaboration

Many brand owners come with ideas or partial formulas. A strong partner will provide formulation assistance, ingredient guidance, and even flavor development to make your vision a reality.

3. Stay Agile for Scale-Ups or Fast Launches

Markets move fast. Whether you need to launch a new SKU quickly or scale production after a viral campaign, a true partner is ready to pivot with you.

4. Support You During Setbacks

Not every batch goes smoothly, and not every campaign hits projected targets. A partner manufacturer will stand by you in difficult moments, offering solutions—not excuses.

Why Transparency + Partnership = Brand Longevity

When nutraceutical brands work with manufacturers who embody both transparency and partnership, the result is a more resilient, trustworthy business.

Here’s how this combination creates long-term advantages:

- Speed to Market: Clear timelines, proactive communication, and collaborative R&D allow you to launch products faster.

- Regulatory Confidence: With a partner focused on compliance and traceability, you reduce your risk of costly recalls or legal issues.

- Consumer Trust: Being able to tell a clean, honest story about how your product is made builds loyalty and increases repeat purchases.

- Innovation Pipeline: A manufacturing partner who understands your brand can help you ideate and formulate your next wave of products.

Real-World Example: Nutraceutical Brands Scaling Through Strategic Partnerships

Let’s consider a scenario. A growing sports nutrition brand is preparing to launch a new line of powder supplements focused on muscle recovery. They need:

- A fast turnaround on formulation and sampling

- Transparent sourcing for key ingredients like BCAAs and electrolytes

- Flexible MOQs as they test multiple SKUs in parallel

- Clear timelines for packaging and labeling approvals

A transactional manufacturer might get bogged down in quoting delays, unclear testing protocols, and rigid order requirements.

But a transparent, partner-driven manufacturer would:

- Assign a dedicated team to the brand

- Offer alternate ingredient options based on lead times

- Provide real-time updates through a shared project tracker

- Ensure compliance across different markets (e.g., US, EU, LATAM)

The difference? A smooth launch, loyal consumers, and a brand that’s ready for scale.

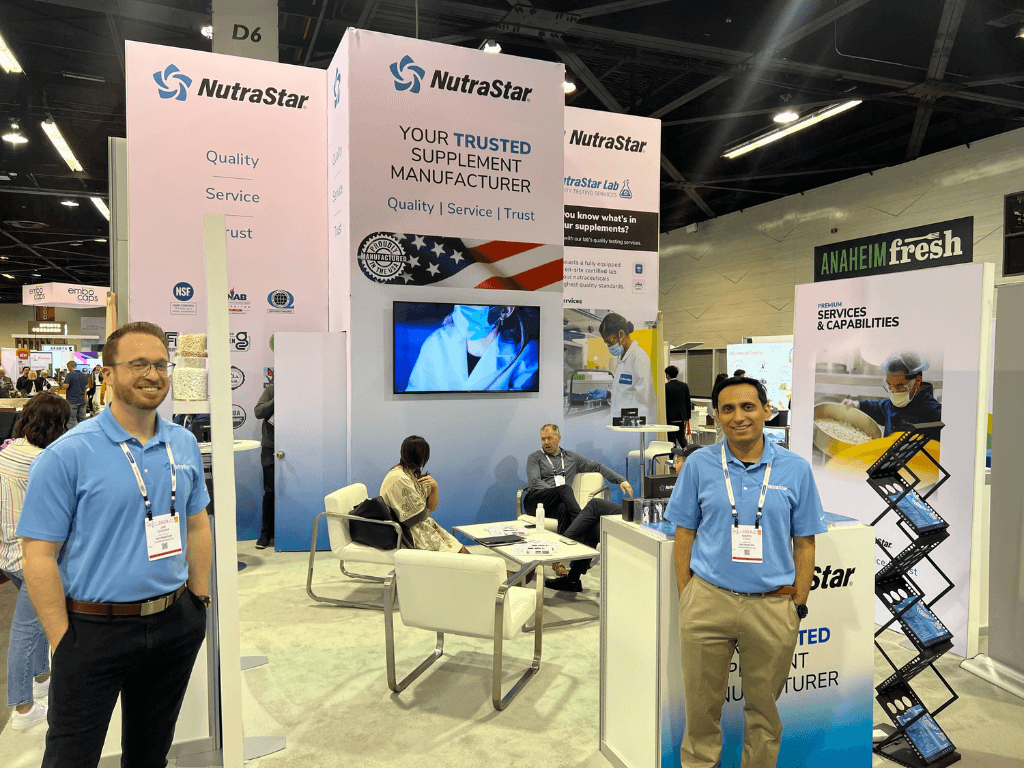

How Our Powder-Dedicated Facility Supports This Vision

To fully embrace transparency and partnership—especially for powder products—we recently launched our state-of-the-art manufacturing facility in Chandler, Arizona.

This expansion wasn’t just about more capacity—it was about building a better model for supplement production.

A Few Highlights:

- Cross-Flow Manufacturing Design: Optimized layout that increases efficiency, reduces production time, and minimizes cross-contamination.

- Industry Experts: A veteran team with over 20 years of experience in powder formulation and blending.

- Location Advantage: Proximity to key suppliers and western shipping hubs—reducing freight times and costs for brands on the West Coast and beyond.

- Sustainability-Forward: Energy-efficient equipment and systems designed to minimize waste and support clean operations.

This new facility reinforces our commitment to helping brands bring quality powder supplements to market—with faster timelines, higher transparency, and smarter collaboration.

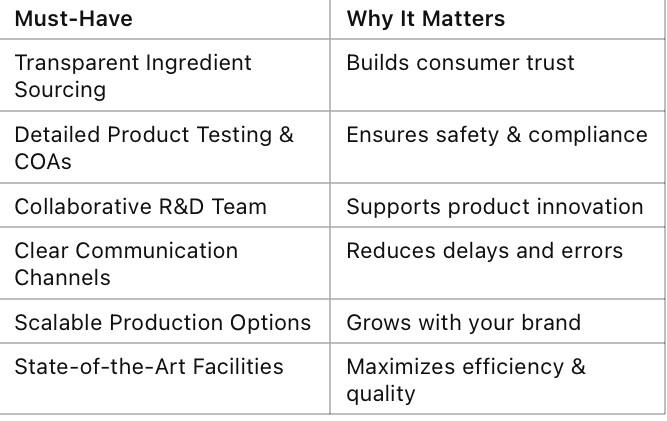

What You Should Look For in a Manufacturing Partner

As you evaluate manufacturing partners this year, here’s a quick checklist to guide your selection:

Choose a manufacturer who isn’t just a vendor—but a true extension of your brand.

Let’s Build Something Great Together

If your brand is preparing to launch a new powder supplement—or if you’re ready to switch to a partner who offers the transparency and care your products deserve—we’d love to talk.

Our powder-dedicated Nutrastar West facility in Arizona is fully operational and ready to support your next launch. From ideation to delivery, we’ll be by your side with open communication, reliable quality, and a partnership mindset.