Built to Perform. Designed to Impress.

We don’t just press tablets—we craft them with precision. Every batch is produced using high-speed, automated lines backed by real-time data from our ERP system, ensuring consistency in weight, hardness, and disintegration from start to finish. With GMP, FDA, and UL certifications—plus our in-house ISO 17025 lab—you can expect pharmaceutical-grade results every time.

Tablet Options & Capabilities

We offer a wide range of tablet formats and finishes to match your product goals and customer experience:

- Formats: standard tablets, chewables, sublinguals, effervescents

- Coatings: clear, colored, or film-coated for taste and shelf stability

- Shapes & sizes: round, oval, custom tooling available

- Functional release: immediate, sustained, or time-release

- Imprinting: for branding or dosing clarity

Whatever you’re formulating, we’ll help you find the perfect delivery.

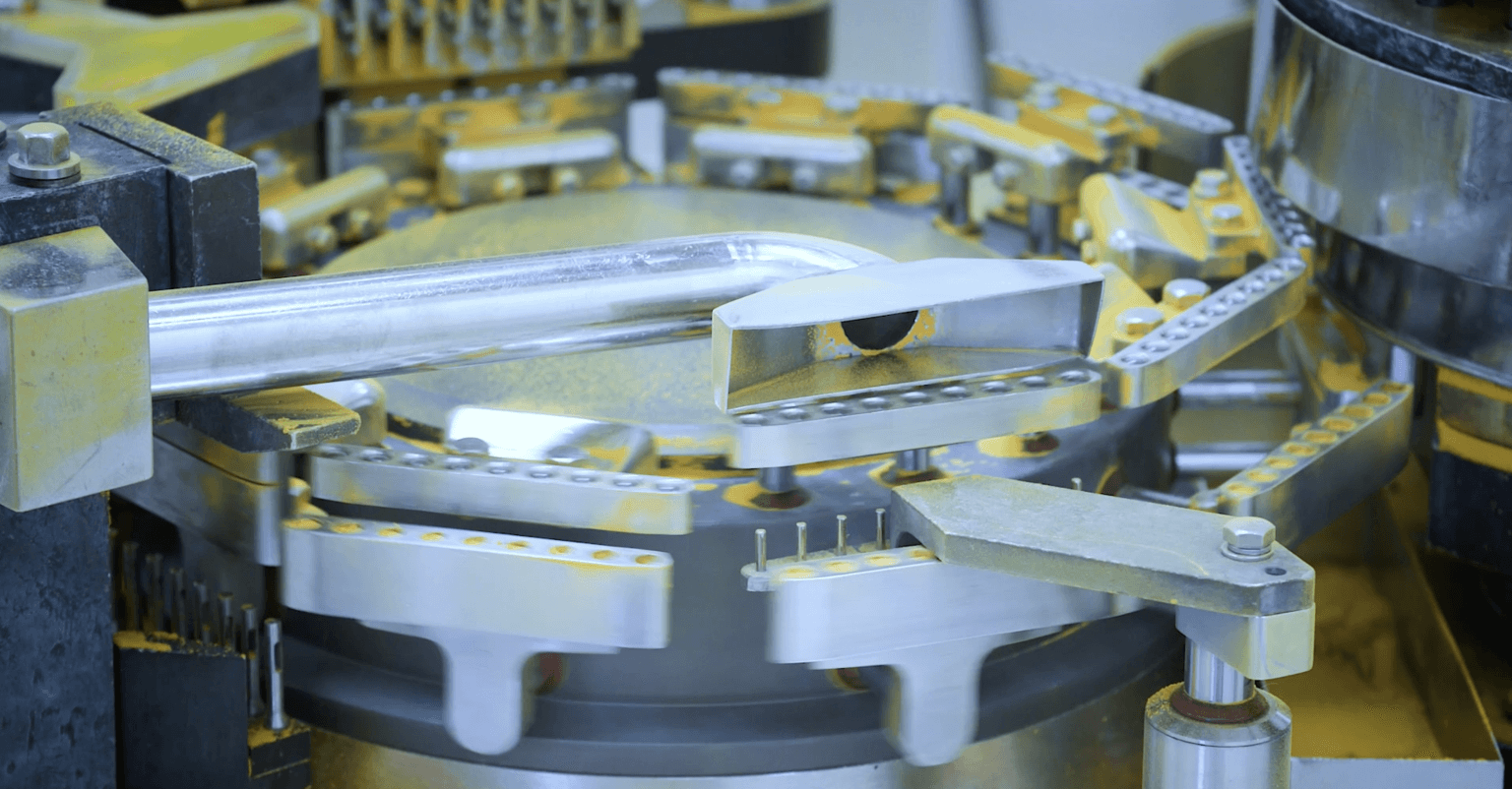

Tablet Manufacturing Process

Every step is built for precision and scale:

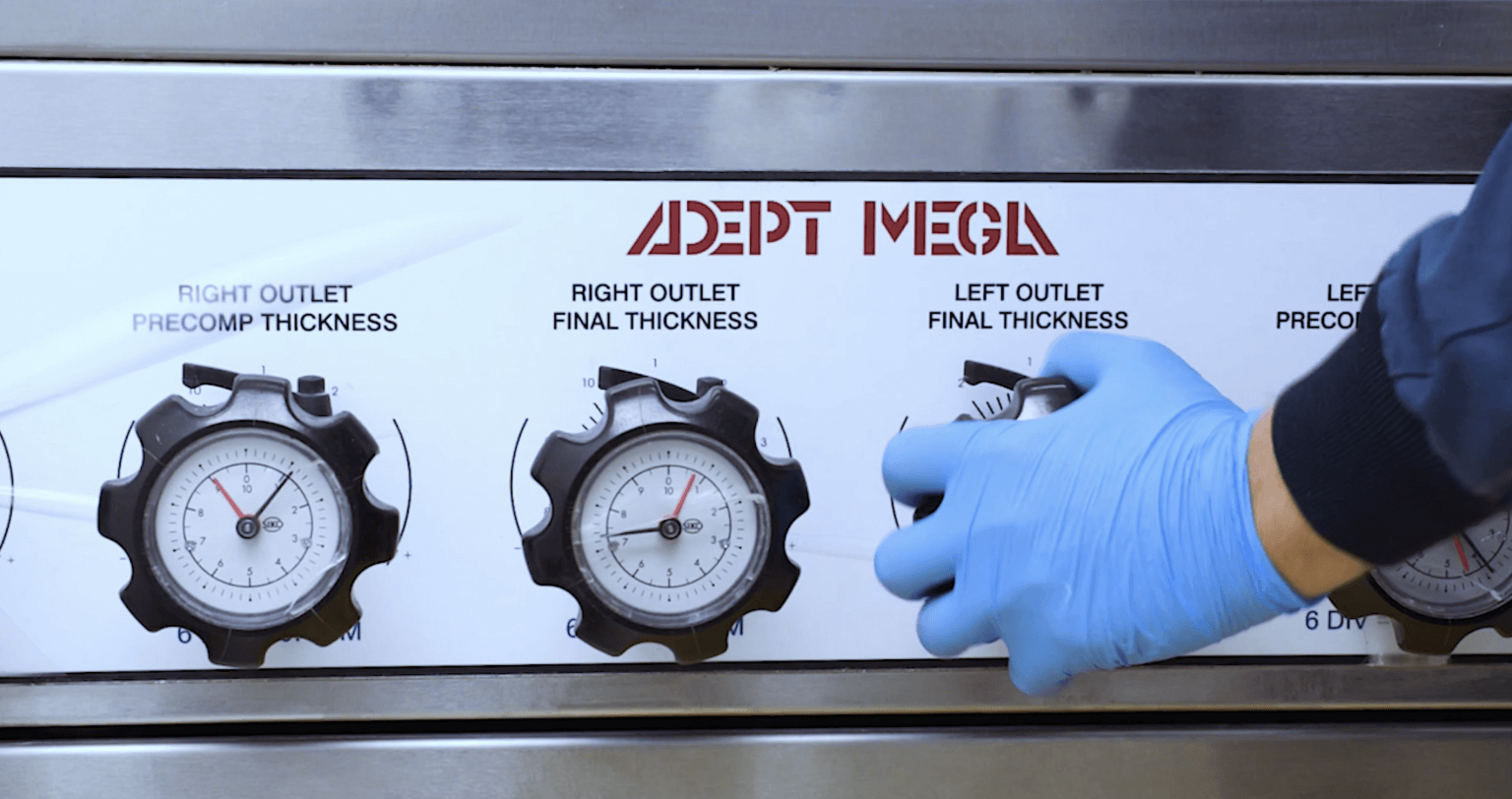

- Fully automated tablet presses with real-time monitoring

- In-line quality control for hardness, thickness, and weight

- Moisture, heat, and dust control systems for maximum stability

- Scalable production — from pilot runs to full-scale national rollout

Efficiency without compromise. That’s the NutraStar way.

Tablet Formulation Support

“Need help dialing in your tablet blend?”

From compressibility and binders to release profile and mouthfeel, our R&D team works side-by-side with yours to get the formula just right — and press-ready.

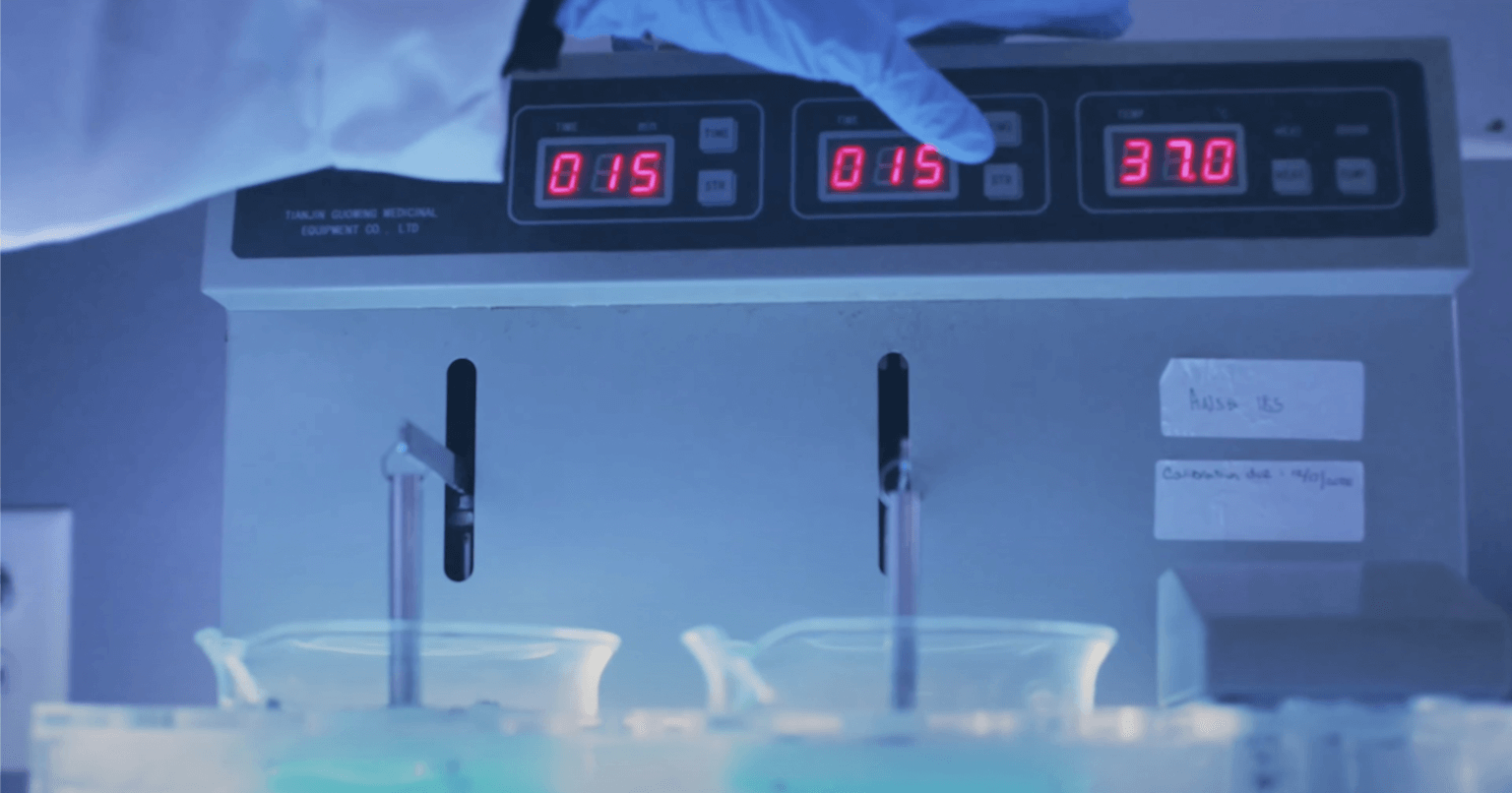

When We Say Quality, We Back It Up

At NutraStar, quality is more than a checklist — it’s a culture. Our certifications speak for themselves: cGMP, FDA compliant, UL certified, and one of the only ISO 17025-certified in-house labs in the industry. Data, oversight, and total accountability for every batch we produce.

Packaging Options

We support a variety of packaging solutions designed to protect and elevate your product:

- Bottles, canisters, and bulk

- High-speed labeling and tamper-proof sealing

- Fulfillment, storage, and shipping services are available

Compliance & Testing

- 3rd-party lab testing upon request

- Label compliance review & ingredient verification

- Full traceability and documentation at every stage

Why Brands Trust NutraStar

- Decades of tablet manufacturing experience

- Millions of units produced with zero recalls

- Seamless onboarding, white-glove service

- Fast lead times, transparent communication, and reliable results

We’re not a broker — we’re your partner in growth.

Frequently Asked Questions

What product formats do you manufacture?

What are your minimum order quantities (MOQs)?

Can I customize capsule size, tablet shape, or powder blend?

What packaging options are available?

What quality and compliance standards do you meet?

Capsules

We produce high-quality hard and soft gel capsules with precise dosing and consistent quality, meeting the highest industry standards.

Tablets

Our tablet manufacturing delivers optimal bioavailability and dissolution, with rigorous quality control ensuring precise specifications.

Powders

We create high-quality nutritional powders with precise ingredient blending and optimal packaging for maximum stability and shelf life.

World-Class Facilities

Located in Chandler, AZ and Farmingdale, NJ, our combined 250,000+ sq ft facilities produce high volumes of quality capsules, tablets, and powders to custom specifications. We ship directly to any location in the world.

Your Trusted Manufacturer

Our capacity to consistently deliver high volumes of quality supplements has made us the manufacturer of choice for hundreds of companies throughout the U.S. and around the world.